OUR SOLUTION

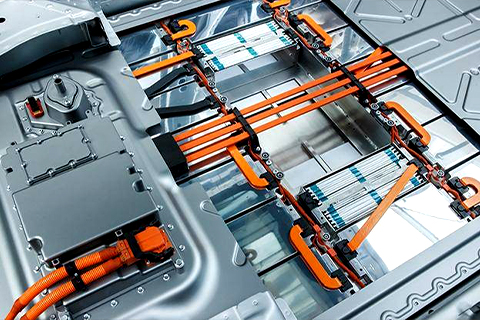

QED Battery Corp. aims to commercialize its high charge density, fast charging rate, long lifecycle, and environmentally sustainable battery technology.

The technology is poised to overcome the limitations of current lithium-ion batteries, offering a more efficient and cost-effective solution for all energy storage needs. The technology is built using abundant, economical materials, offering superior performance and safety compared to traditional lithium-ion batteries.

QED will leverage its Canadian roots to take full advantage of Federal and Provincial programs that support R&D.

BATTERY TECHNOLOGY

High energy density with environmentally sustainable with no lithium or cobalt – fully and easily recyclable. Materials are readily available from a conflict-free supply chain.

Production process is inexpensive as it does not use toxic or combustible materials – batteries don’t catch fire. Multi-purpose storage opportunity from grid, EV, and consumer goods with a clear competitive edge over existing lithium-ion and solid-state technologies.

Predicted cycle life of 10,000 cycles.

Charging from 0-90% in minutes.

Same or better energy density than current Lithium-ion Technology.

Expected market price well below USD $100 / kWh.

THE SCIENCE

The QED battery technology is based on common anode and cathode materials in an alkaline environment infused with nanomaterials to create a hybrid potassium-ion battery. The active metal oxides are dispersed using nanomaterials to enhance utilization and rate capabilities.

The next stage of product development will be to further examine the properties of the materials under controlled conditions to better understand how these impact performance and operating lifetime of the cells.

This will make use of the infrastructure and electrochemical expertise available at Ontario Tech University. Sheldon Williamson, PhD, electrochemistry, and Bradley Easton, PhD, MCIC, C. Chem.

Technology Readiness Levels

Line of research has been validated.

Current viable specifications for our separator need to be optimized.

Next stage of investment will be to finalize material formulations which need to be fine-tuning a highly specific separator.

Objective is to have a near-market-ready battery system being field-tested within 18 months.

In Q1 2025, QED will start to manufacture cells in volume, battery packs, and a battery management system for real-world testing.

Q4 2025, QED expects to have pre-market battery systems for field testing.

PROTOTYPE DEV & TESTING

QED has built and tested prototypes to demonstrate its technology.

Bench testing has demonstrated a series of cells, charged for less than 2 minutes, can be put under load and power a string of Christmas lights for 4 hours.

New prototypes have an advanced separator, and optimized chemistries and structures resulting in energy densities ranging from 1.6 mAh/cm² to 5 mAh/cm². Comparable to and exceeding some of the best-performing lithium-ion solid-state batteries in use today.

Government Support

QED has leveraged public grants from its inception to move the project forward. The company will continue through to the commercialization stage to secure support from government and industry partners to leverage every dollar of capital investment. It is critical to note that all the government granting organizations continue to evaluate the progress of QED and will cease funding if the opportunity is no longer viable. The current capital raise will support QED’s portion of the grants.

The Six Key Criteria To Commercial Viability

Specific Energy, in Wh/kg

Research suggests that the theoretical limit to QED energy density could be up to 600 Wh/kg. We are working to achieve 150 Wh/kg by 2025 with an ultimate target of 250-300 Wh/kg by 2030.

Manufacturing Cost per kWh

With abundant and low-cost raw materials used in QED technology, coupled with a straightforward manufacturing process, we should be able to achieve

Environmental Sustainability

The advantage of QED technology is that it is virtually completely environmentally sustainable from cradle to grave. Materials used in both electrodes are in abundant supply, do not require refining, and can be recycled fairly easily.

Life Cycle

QED cells behave like a hybrid super-capacitor and should result in fewer imperfections over time, reducing degradation and significantly increasing longevity to at least 10,000 cycles (defined as being charged from 0%-100% and discharged back to 0%).

Charging Rate

We have demonstrated that a QED cell can be charged to 100% within 3 minutes. There appears to be limited resistance to very high power input and no discernible issues with overheating or structural damage.

SAFETY

In simple terms, the QED battery chemistry is completely safe. It is non-toxic, non-combustible, tolerant to both over-charging and shorting, and is highly scalable without compromising safety.

CONCLUSION

QED technology has advantages in almost every aspect of the commercial viability criteria. There will be improvements in Li-ion chemistry which will benefit EVs, e.g., solid-state, and there are competing chemistries suitable for stationary storage, e.g., flow, sodium salt, etc., but QED will still remain highly advantageous.